1-1. Define the welding process

1-2. Arch welding processes

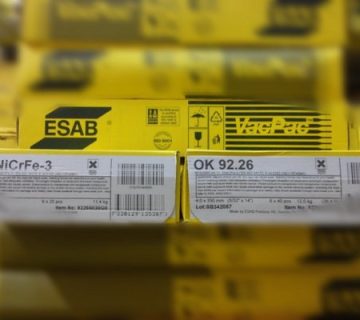

1-2-1. Electrode

1-2-2. Tungsten arc welding with a protective gas cover

1-2-3. Metal arc welding with a protective gas coating

1-2-4. Sub -powder arc welding

1-1. Define the welding process

Welding is the connection of two or more metal pieces by applying pressure, heat or both, without the addition of a filler metal, which eventually leads to a uniform area at the border of two pieces by melting or crystallization.

Ideal welding can be referred to as an connection that cannot be distinguished from other parts. Ideally, welding a special alloy using a filler metal that is fully compatible with the base metal will have the following advantages:

-The uniformity of the compound in the welding bond.

-Excellent matching physically.

-Uniform mechanical properties in the weld and base metal area after the heat treatment of the weld area

1-2. Arch welding processes

1-2 1-1- Welding with a coat electrode (manual electrode) (SMAW-MMAW)

This method is one of the arc welding processes in which the arc is established between the cover electrode and the molten dock and provides the heat needed for welding. This type of process is suitable for welding all types of metals with any thickness. It is that the flux provides the required to protect the pond by creating slag and gases produced from burning coatings. In this process, the quality of the weld depends largely on the welding skill.

1-2-2- Tungsten arc welding (GTAW-TIG)

In this process, commonly called tig weld, heat is produced through an arc that passes through the neutral gas between the non -consuming electrode and the workpiece. The electrode is in this method of tungsten, tourium and roop alloys. Protective gas can be argon or helium or a combination of the two, which should be minimum purity of 99.95%. In this method, the nutrient or filling metal contacts the arch and feeds it.

This method is mainly used to create a root pass and in particular for the welding of pipes.

1-2-3- Metal Arc welding with protective gas coating (GMAW-MIG, MAG)

In this method, bare boiling wires are used and the molten cos and pond are protected by the destructive effect of the atmosphere by an external source of gas.

The high welding current used in this method results in an increase in the sedimentation rate by up to 6 kg / h. When the protective gas is neutral in this process, the MIG is called the MAG process if the gas is active.

Neutral gas is in the process of MIG argon, helium or a combination of it, and in the TIG process, CO2 gas or a combination of this gas with a small percentage of other gases.

1-2-4- Subcutaneous arc welding (SAW)

This method is an arc welding with continuous bare wire that is automatically fed into the arc and creates the arch heat between the metal wire and the workpiece. This is a high -powered process that is used in a semi -automatic or fully automatic process. When used instead of wires, straps (strips) are called strip. Sometimes the wire is also used to feed the welding pond instead of bare wires.

The welding is done under the cover of a layer of seed lubricant (powder). In this process the arc is hidden and the secretion or smoke is not produced and has a very high sediment rate. This method is suitable for horizontal welding and requires specific techniques for vertical state. Sub -powder welding is suitable for a wide range of steels, inchonel and monols and other non -ferrous metals.