According to international standards, according to the type of base metal and the service used, the electrode, filler and welding powder are selected. To determine the diameter of welding materials, including electrode and welding fillers, the thickness of the piece and the connection design must be specified.

The most important standard in the world to select electrode and welding fillers according to base metal is AWS.

SFA – A5.1 family fillers and SFA -A5.18 family fillers are used for welding simple carbon steels, the most consisting of which are the following items:

E 6010 E 7016 E 7024 ER 70S-3

E 6013 e 7018 e 7028 ER 70S-6

SFA – A5.5 family electrodes and SFA -A5.28 family fillers are used for welding low alloy steels, the most widely used:

E 7010-X E 8010-X E 9010-X E 10018-X ER 70S-X ER 90S-X

E 7018-X E 8018-X E 9018-X E 11018-X 80s-X 100S-X

In this classification the X extension is determined by the type of alloy. Accordingly, the letters A, B, C, D and G include electrodes and letters A, B, D, G and Ni fillers.

Letter A represents low -alloy carbon steel with molybdenum.

The letter B indicates low alloy steel with chrome and molybdenum.

The letter C represents low alloy steel with nickel.

Letter D indicates low alloy steel with manganese and molybdenum.

The letter G represents low alloy steel with manganese.

And the letter ni selected for the fillers indicates low -alloy steel with nickel with molybdenum or malebdenum.

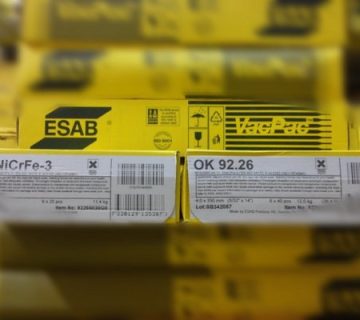

SFA – A5.4 family fillers and SFA -A5.9 family fillers are used for welding stainless steels, the most consisting of which are the following items:

E307-X E310-X E318-X E410-X

E308L-X E312-X E320-X E430-X

E308H-X E316L-X E347-X E2209-X

E309L-X E317-X E385-X E2509-X

The X extension in the family’s family consists of 5 numbers, which represent the type of electrode coating, welding polarity and a number of other parameters. These numbers are 15, 16 and 17 and are 25 and 26.

ER 308L ER 309L ER 310 ER 316L ER 318 ER 385 ER 2209

ER 308H ER 309MOL ER 312 ER 317L ER 347 ER 410 ER 2509